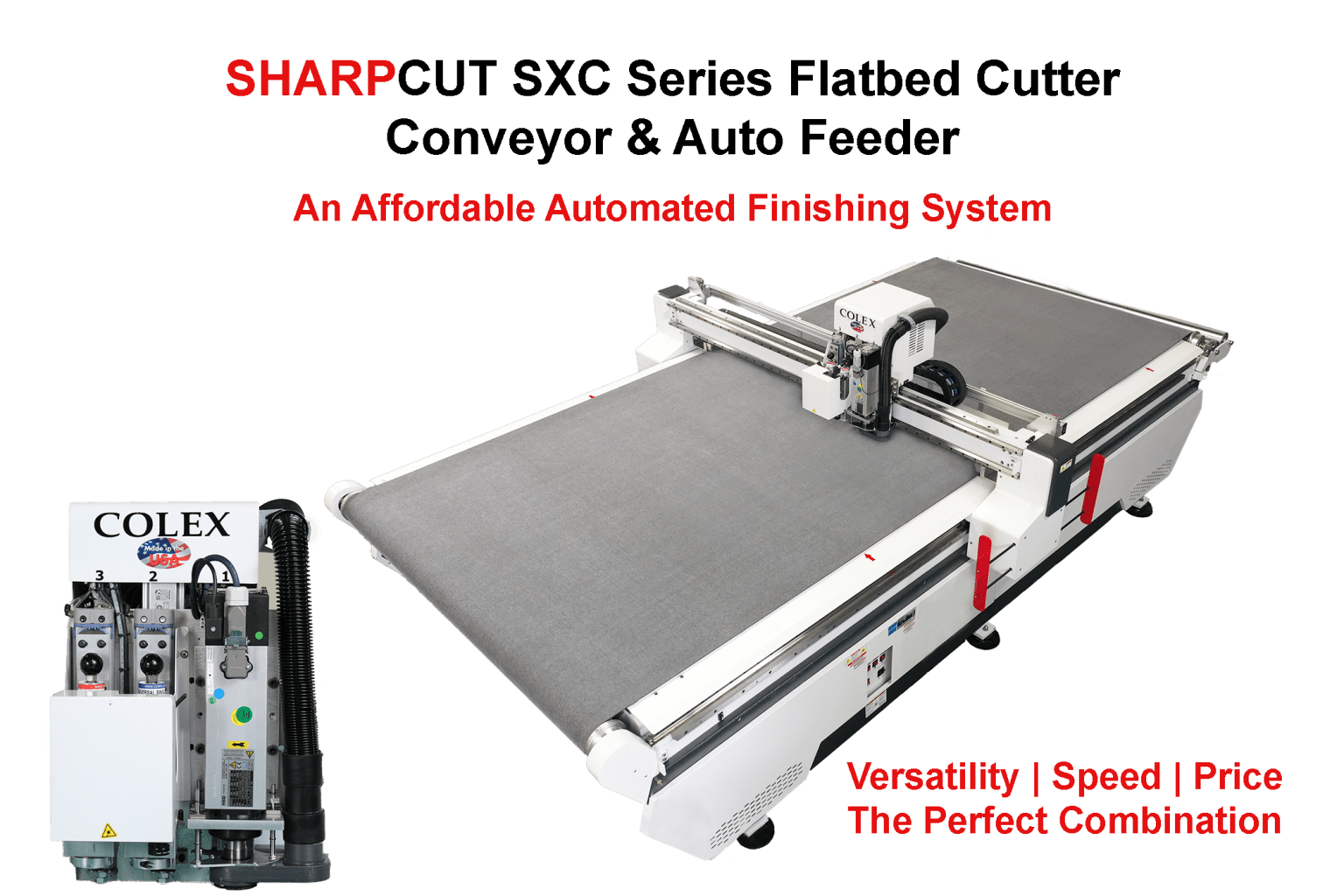

The Colex Sharpcut SXC Digital Flatbed Cutter is an exceptionally affordable cutter for those looking to grow their business. This complete turnkey solution will help automte the print service provider’s workflow and reduce costs associated with the finishing process of large format goods. This will open the doors to new opportunities, reduce costs, and help increase production while tapping into new revenue streams.

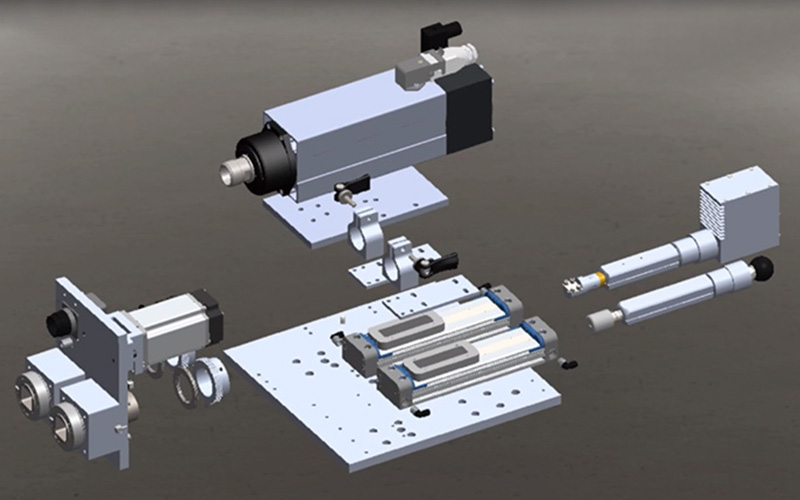

The unique design of the Colex Sharpcut’s triple interchangeable tool head allows your operator to transition from routing, knife-cutting, and kiss-cutting rapidly. By default, the Colex Sharpcut includes a fixed knife, an oscillating knife, and a router, allowing you to maximize the full capability of the table for a multitude of applications. Optional add-on tools are available for customization to suit your specific needs and workflow.

The Colex Sharpcut is a fully integrated hardware and software solution that turns your digital cutting table into a true short-run production system. This powerful solution provides unmatched productivity by intelligently finishing your graphics with the highest accuracy and efficiency.

It includes a camera system powered by Colex Cut Center that individually adjusts your cut files to accurately match your printed graphics and read any diameter registration mark, crop mark or square resulting in highly efficient production.

Vision Registration Video

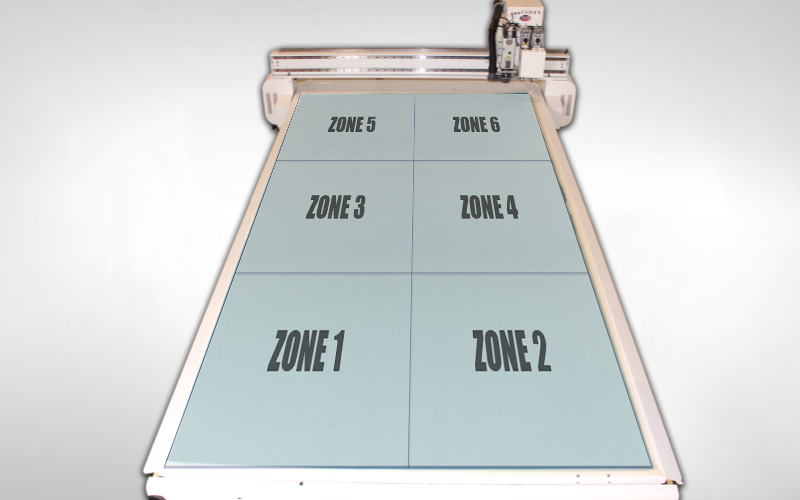

The work surface is divided into six zones for the 67″×126″ and 126″×64″ models, four zones for the 67″×67″ model, and sixteen zones for the 126″×126″ model. Each zone has its own vacuum pump controlled by individual electrical “on/off” buttons on the front panel. The power of the pumps is configured for most substrates used in large format printing.

Our cutting table is designed for cutting sheet and rigid materials while delivering clean, smooth edge quality. The gantry is made out of Aerospace aluminum alloy, strong enough to accommodate the optional 3HP Router. The cutting surface of the machine can withstand 1,000+ pounds of pressure.

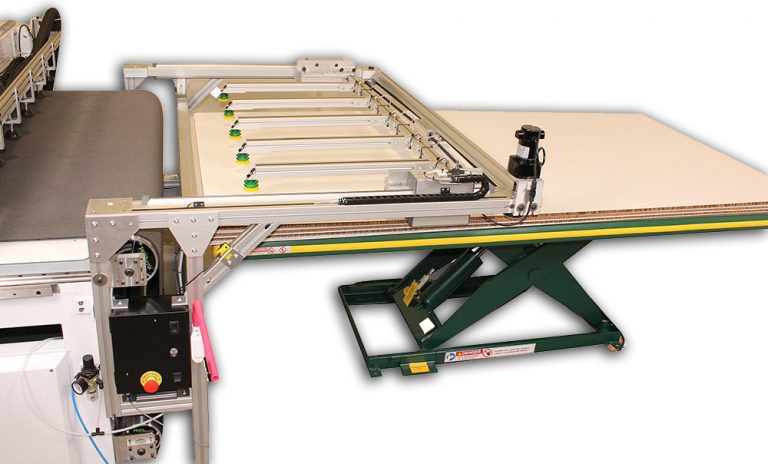

Automatic Board Feeder

The automatic board feeder is designed to load semi-rigid to rigid boards from the pallet table onto the conveyor belt. It is designed to work with a large array of material sizes and thicknesses.

Pallet Table

When used with the Automatic Board Feeder, the pallet table will automatically maintain the material height. The pallet table drops down to 6″ in height for easy loading and unloading.

Clamping Bar

The clamping bar ensures that the material advances at the same rate as the belt while advancing down the table. The clamping bar is to be used in conjunction with either the Roll Feeder or the Automatic Board Feeder to ensure consistent material placement before cutting.

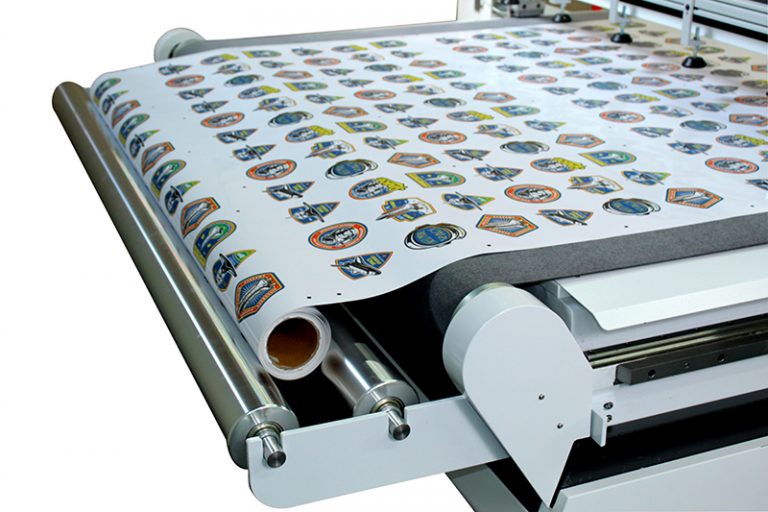

Roll Feeder

For manual and automatic feeding of flexible rolls.