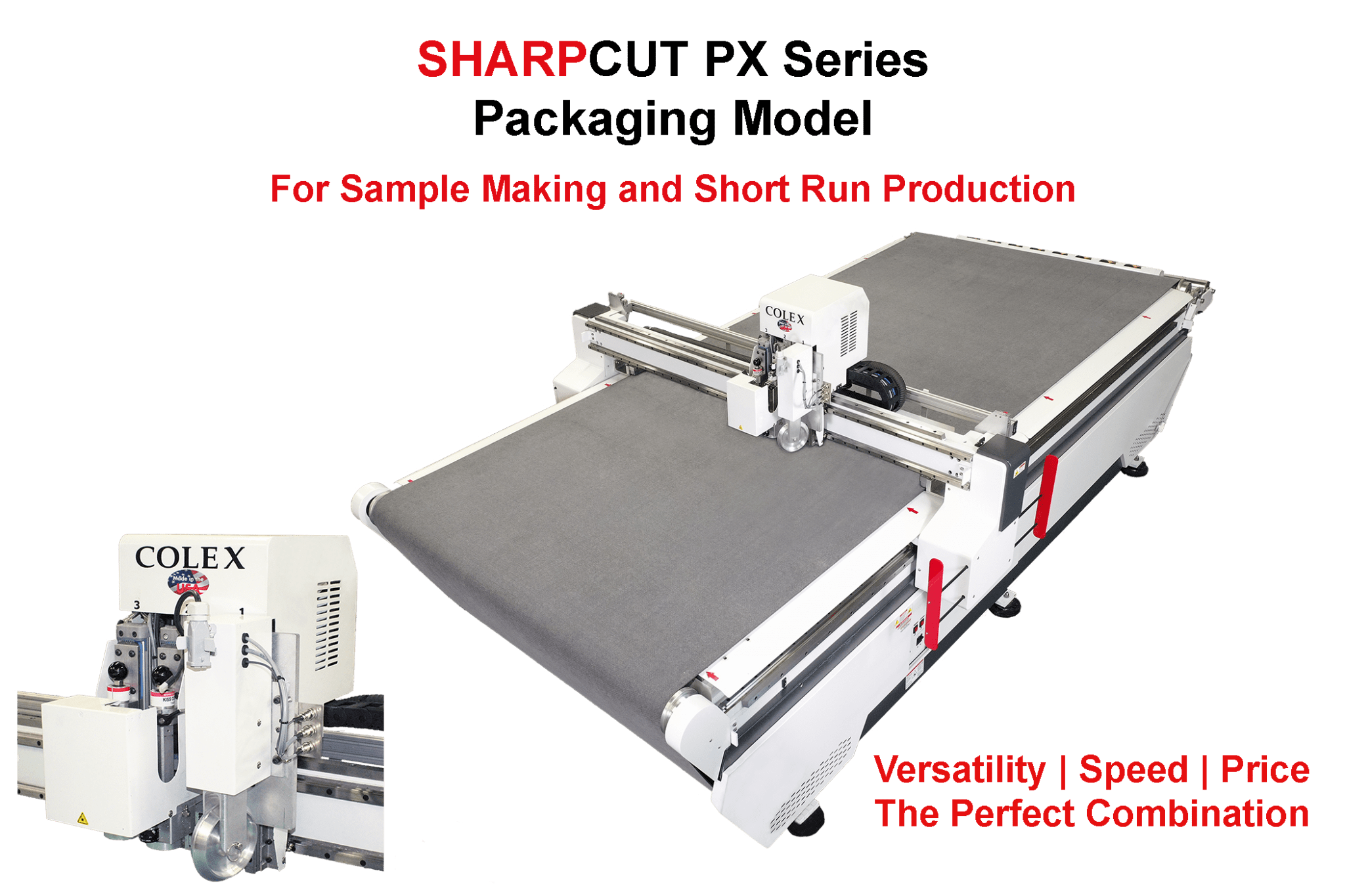

Wide Format Finishing Just Got Easier

- Increased Acceleration & Cutting Speeds

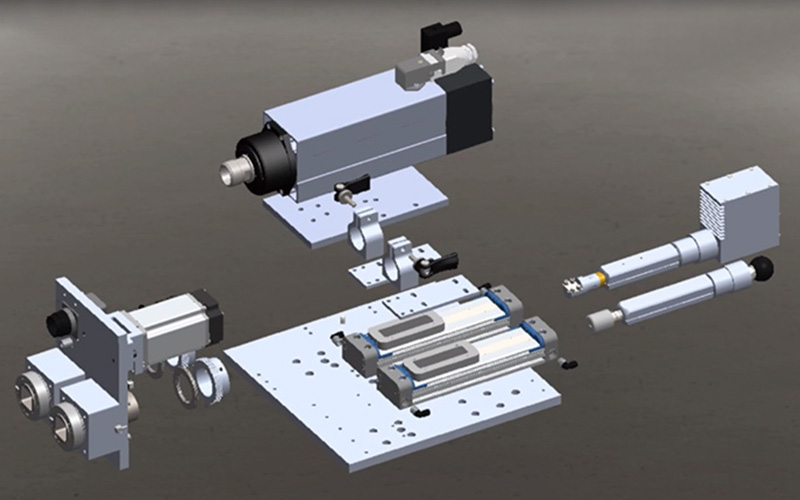

- Triple Interchangeable Tool Head

- Vision Registration System & Camera

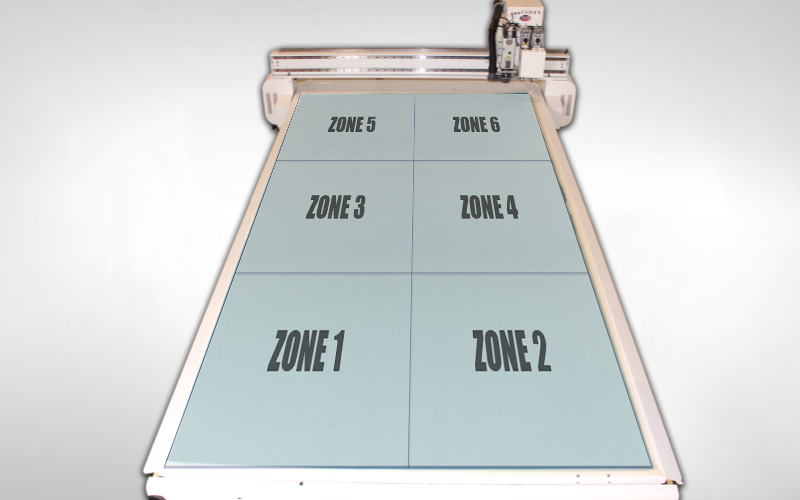

- Energy Efficient 6-Zone Vacuum System

- Solid Steel Welded Frame

Packaging:

Samples are produced easily for accurate cutting and creasing on a full range of materials including micro flute through triple wall corrugated, honeycomb, foam, chipboard and paperboard.

Graphics:

Full color samples or printed short run jobs can be cut and creased quickly eliminating printing plate cutting and dies.

Optional:

The Sharpcut is available with a conveyor belt and automatic board loader increasing productivity and efficiency.

The unique design of the Colex Sharpcut’s triple interchangeable tool head allows your operator to transition from routing, knife-cutting, and kiss-cutting rapidly. By default, the Colex Sharpcut includes a fixed knife, an oscillating knife, and a router, allowing you to maximize the full capability of the table for a multitude of applications. Optional add-on tools are available for customization to suit your specific needs and workflow.

The Colex Sharpcut is a fully integrated hardware and software solution that turns your digital cutting table into a true short-run production system. This powerful solution provides unmatched productivity by intelligently finishing your graphics with the highest accuracy and efficiency.

It includes a camera system powered by Colex Cut Center that individually adjusts your cut files to accurately match your printed graphics and read any diameter registration mark, crop mark or square resulting in highly efficient production.

Vision Registration Video

The work surface is divided into six zones for the 67”×126” and 126”×64” models, four zones for the 67”×67” model, and sixteen zones for the 126”×126” model. Each zone has its own vacuum pump controlled by individual electrical “on/off” buttons on the front panel. The power of the pumps is configured for most substrates used in large format printing.

Our cutting table is designed for cutting sheet and rigid materials while delivering clean, smooth edge quality. The gantry is made out of Aerospace aluminum alloy, strong enough to accommodate the optional 3HP Router. The cutting surface of the machine can withstand 1,000+ pounds of pressure.

| MODELS | PX1717 | PX1732 |

|---|---|---|

| Working Area | 67” x 67” | 67” x126” |

| Machine Dimensions | 98” x 90” | 98” x148” |

| Tool Head | Triple Interchangeable Tool Head | Triple Interchangeable Tool Head |

| Camera | Industrial 3.1Mpixel | Industrial 3.1Mpixel |

| Vacuum System | 4 Zone (5 kWatt) | 6 Zone (7.5 kWatt) |

| Rapid Speed | 50 IPS/76 m/min | 80 IPS/122 m/min |

| Acceleration | .86 G | .86 G |

| Bridge Clearance | 4.0” | 4.0” |

| Max. Cutting Thickness | 2.5” | 2.5” |

| Recommended Floor Space | 14' x 14' | 14' x18' |

| Machine Weight | 3,000 lbs | 3,500 lbs |