Sharpcut Flatbed Cutter Details

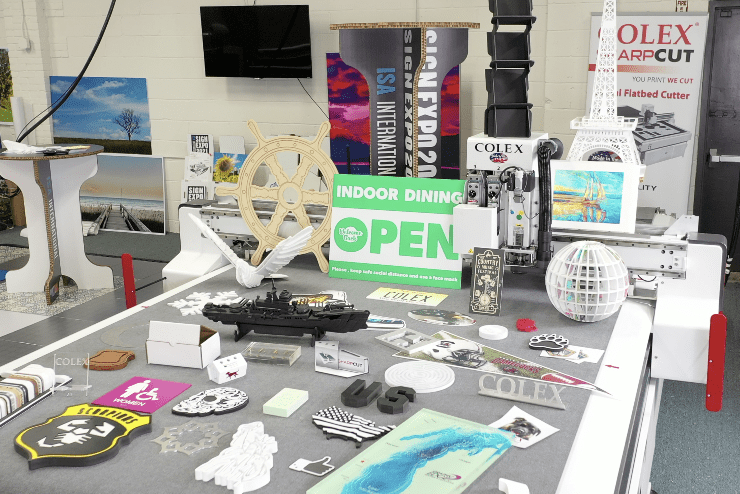

Productivity

The Colex Sharpcut is an affordable solution for those looking to grow their business. This complete turnkey system helps automate your workflow, reduce costs, and increase production. Perfect for packaging, signage, POP/POS displays, and short run production while reducing outsourcing and labor intensive processes.

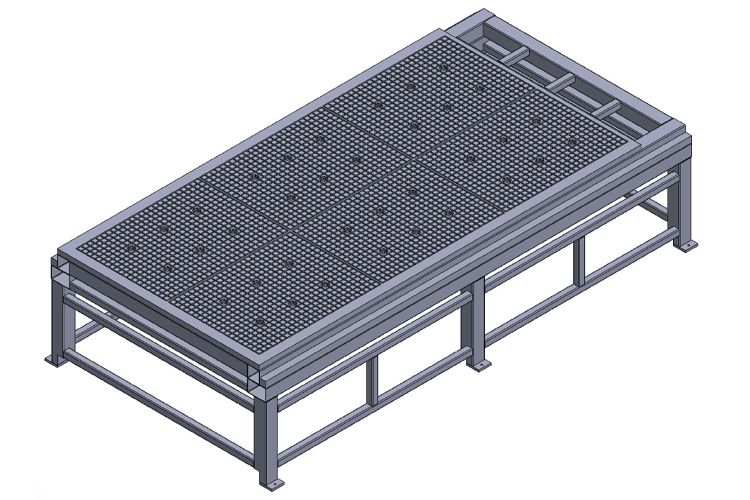

Cut Quality and Precision

The Colex Sharpcut is manufactured with a solid steel welded frame, which increases the strength and reduces vibration while cutting. This ensures the Sharpcut provides a clean finished edge on your materials, with the capability of routing on 2.5” thickness.

Vacuum Quality and Material Hold Down

The work surface is divided into six zones, the 67” x 126” and 126” x 64” models, four zones for the 67” x 67” model and sixteen zones for the 126” x 126” model. Each zone has its own vacuum pump controlled by individual on/off buttons. The pump’s power is configured for most substrates used in large format printing.

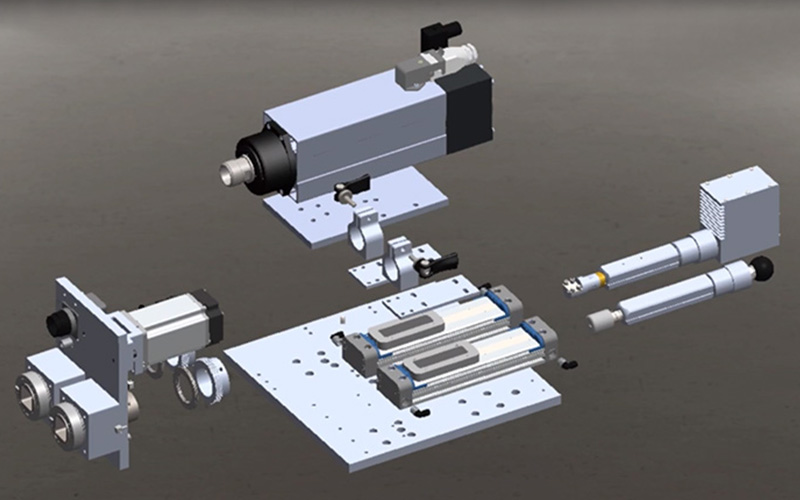

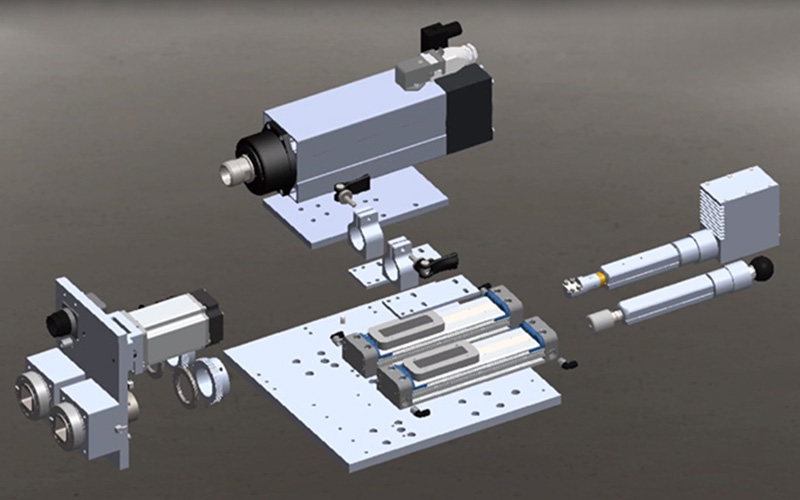

Interchangeable Tool Head

The unique design of the Colex Sharpcut’s triple interchangeable tool head allows your operator to transition from routing, knife-cutting, and kiss-cutting rapidly. It includes a fixed knife, oscillating knife, and a router, maximizing capability. Optional add-on tools are available for customization to suit your specific needs and workflow.

Design Concept

The Colex Sharpcut’s modular design and tool-less change structure simplifies operation and maintenance. You’ll discover the Sharpcut was designed with the operator in mind. All vacuum pumps are front-facing for maintenance access, with dual-zone belt for conveyor feed or flatbed operation. With minimal maintenance, you’ll experience clean cut quality on the Colex Sharpcut.